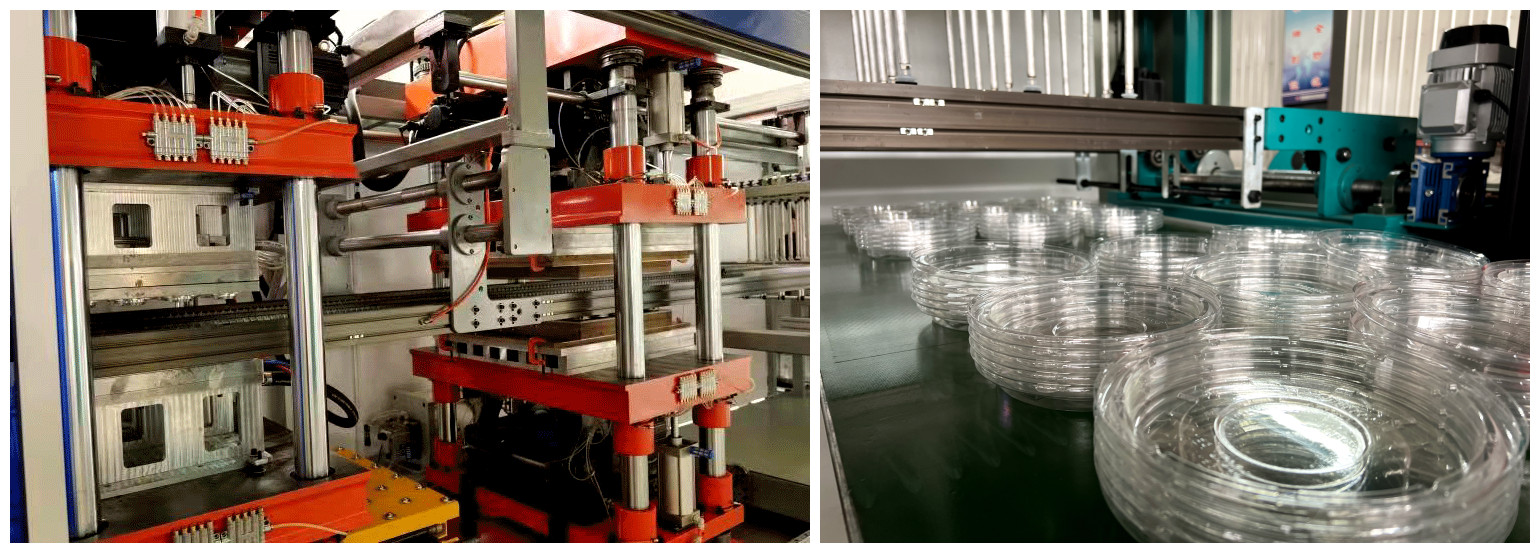

Thermoforming Machine

Home > Thermoforming Machine

A, the function and characteristics:1. Mechanical, pneumatic, electrical integration. Every action is controlled by PLC program. Touch screen operation, simple and convenient.2. Coordinate is negative pressure molding.3. The upper and lower die forming method.4. The server to send piece, infinite le

Product introduction

A, the function and characteristics:

1. Mechanical, pneumatic, electrical integration. Every action is controlled by PLC program. Touch screen operation, simple and convenient.

2. Coordinate is negative pressure molding.

3. The upper and lower die forming method.

4. The server to send piece, infinite length adjustment, high accurate and stable.

5. Upper and lower electric heating furnace more sections.

6. Electric heating furnace temperature control system adopts full computer intelligent automatic compensation control, man-machine interface in partition - control - digital input, has a fine tuning of high precision, temperature uniformity, stability (not influenced by external voltage, temperature fluctuation is less than 1 degree), low energy consumption, energy saving about 15%), the advantages of long service life of the furnace plate.

7. Forming, cutting unit, open mold, mold clamping servo motor control, automatic counting output.

8. Stack products for a variety of ways, for products can be customized.

9. With product information and parameters file memory function.

10. Send caterpillar track width can be synchronous automatic electrical adjustment or division.

11. Electric heating furnace is automatically removed from the device.

12. Mechanical feeding device, reduce labor intensity.

Second, the product parameters:

| Adapt the sheet width of the sheet | Adapt the sheet thickness | Maximum sheet roll diameter | Power consumption | Maximum forming area | Mold width | Maximum forming depth | Maximum cutting area | Cutting force |

| 750mm | 0.12-2.0mm | 800mm | 30-50kw/h | 720*770mm | 720mm | 125mm | 720*770mm | 80T |

| Work efficiency | Product shaping and coolong | Using electric | Maximum heating power of electric furnace | Maximum power of the whole machine | Maximum power of the whole machine | Total Weight | Applicable materials | |

| 40cycle/min | Water cool | Three-item four-wire system 380v50Hz | 190kw | 36kw | 15000*3000*2750mm | 13T | PET,PP,PVC,APET,PETG,PS,PLA | |

About Us